SMAPOL® fibre – SMAPOL® stabiliser – SMAPOL® reinforcement.

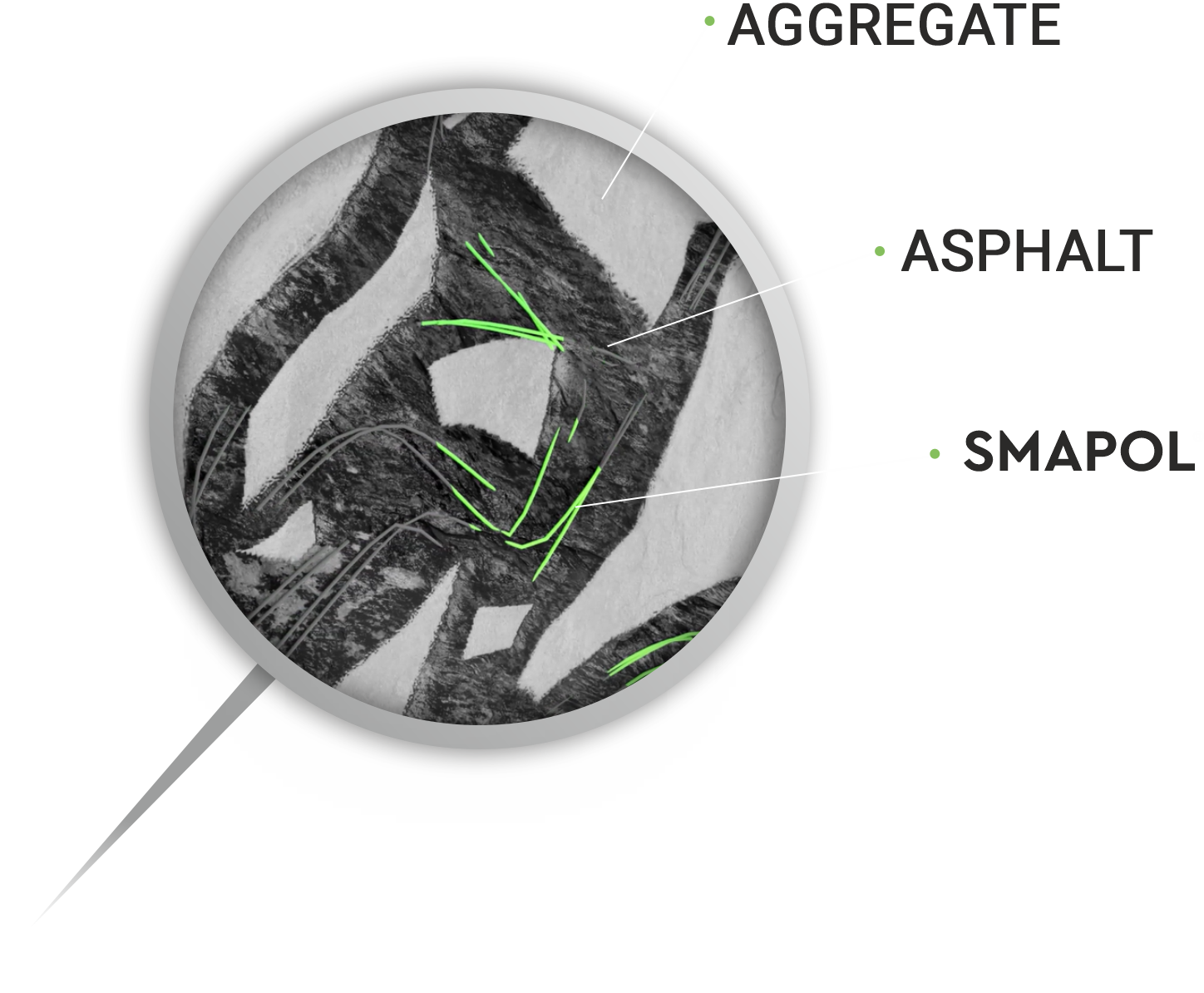

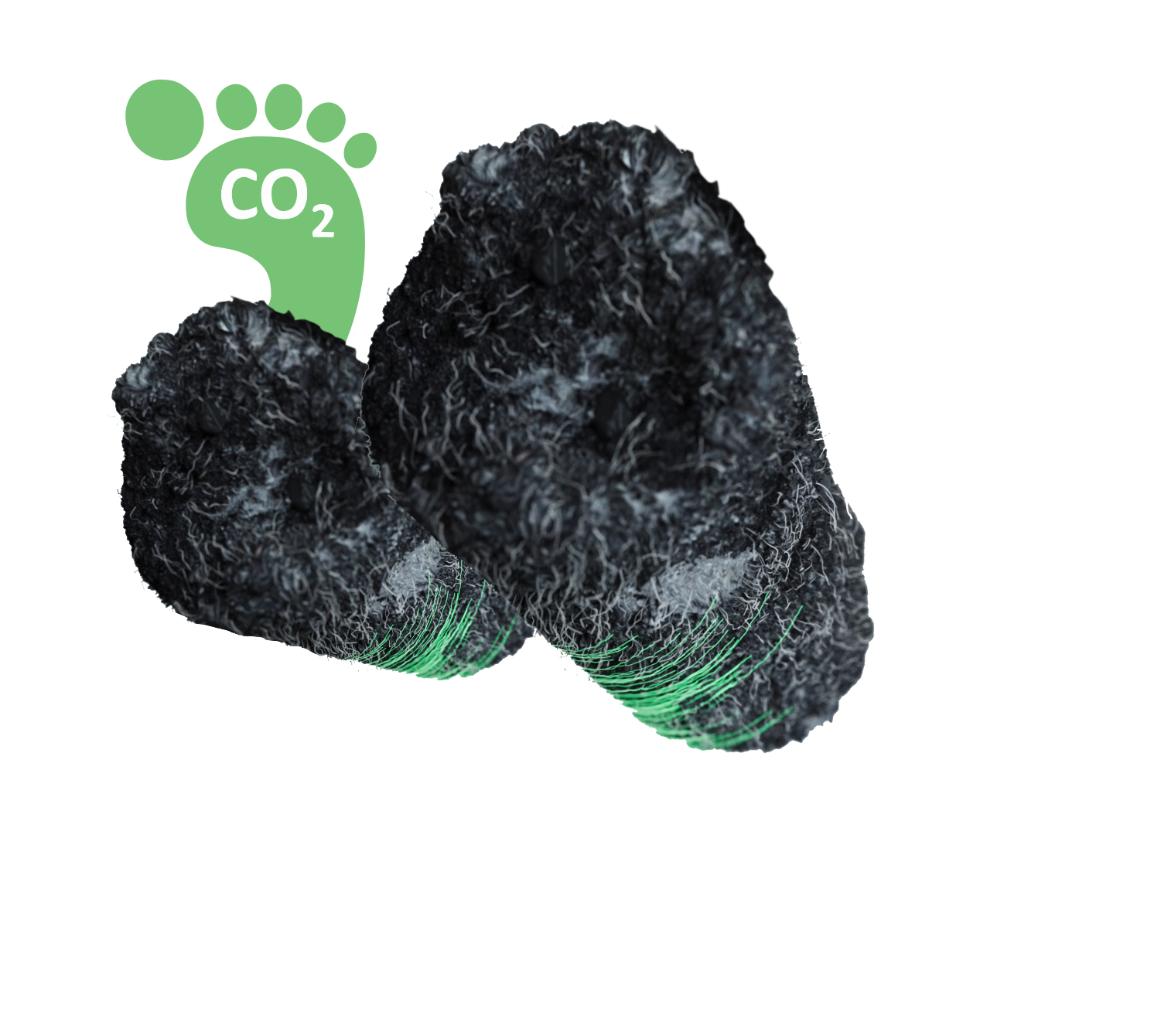

SMAPOL® is an innovative fibrous additive for mineral-asphalt mixtures in granulated form, produced from recycled textile cords recovered from the recycling process of used tyres.

SMA and other gap-graded asphalt mixtures usually contain stabilising components to provide resistance to delamination, segregation and binder drainage (bitumen + mineral particles with a size smaller than 1 mm).

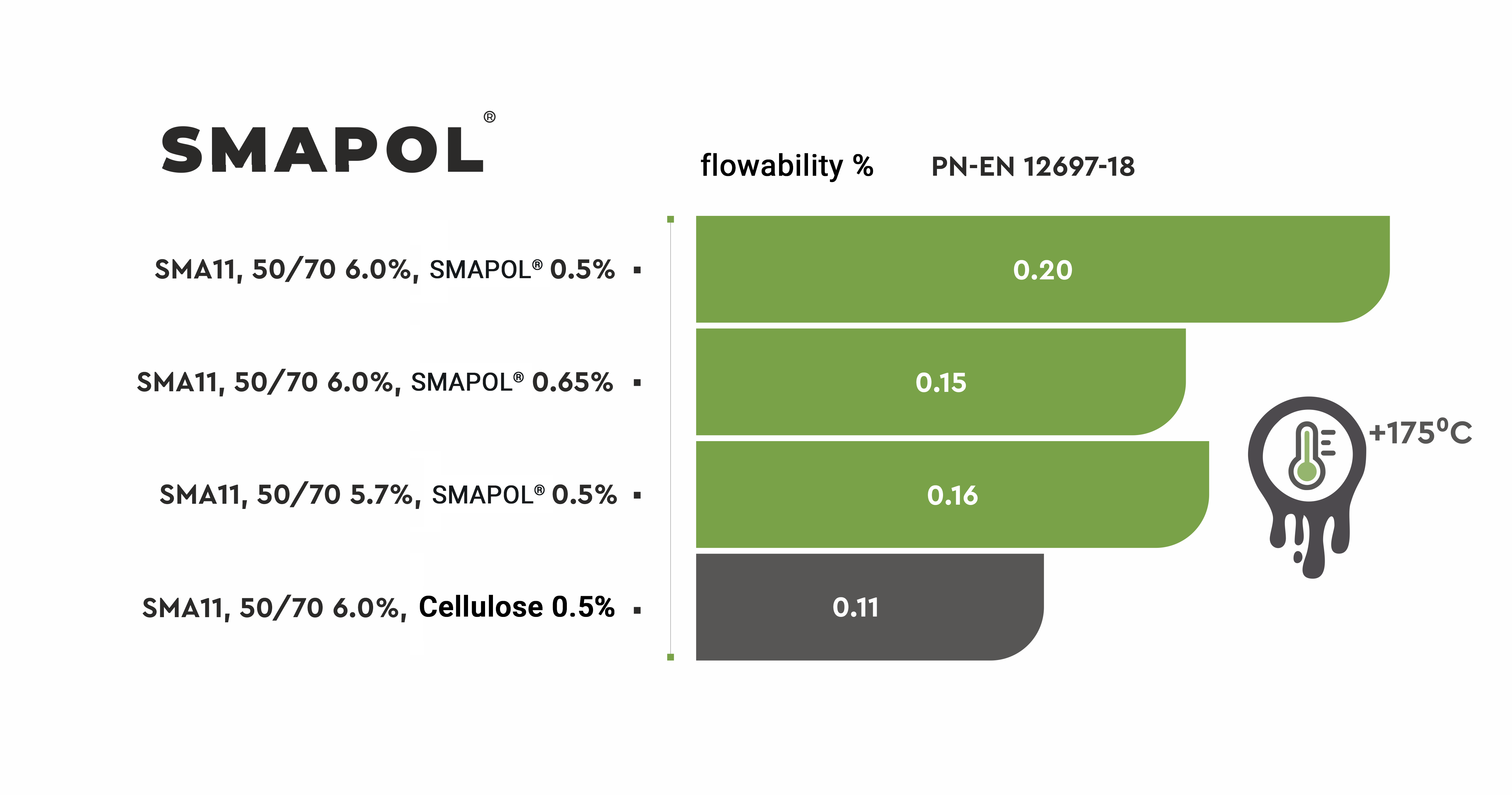

SMAPOL® fibres prevent binder drainage in SMA and other gap-graded asphalt mixtures.

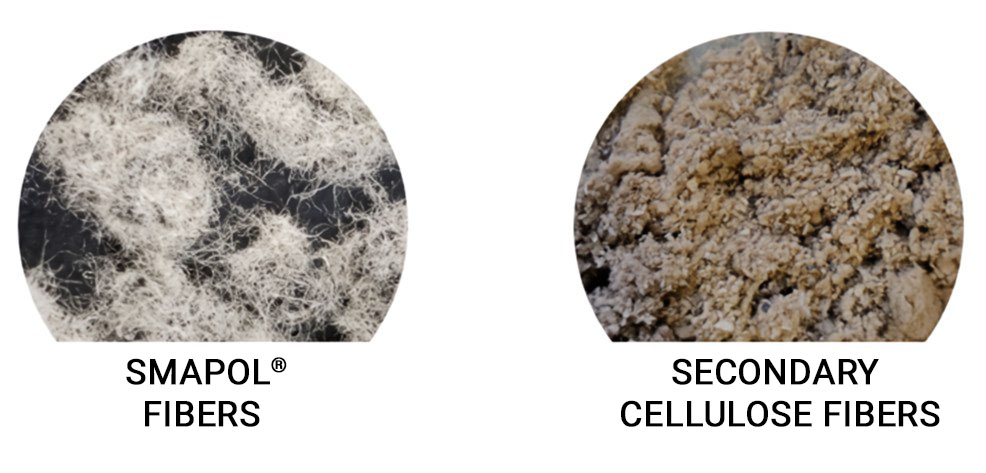

It is often the case that secondary cellulose fibre from recycled paper processing, for example granulated with bitumen, is used to stabilise the binder due to its high adsorption capacity.

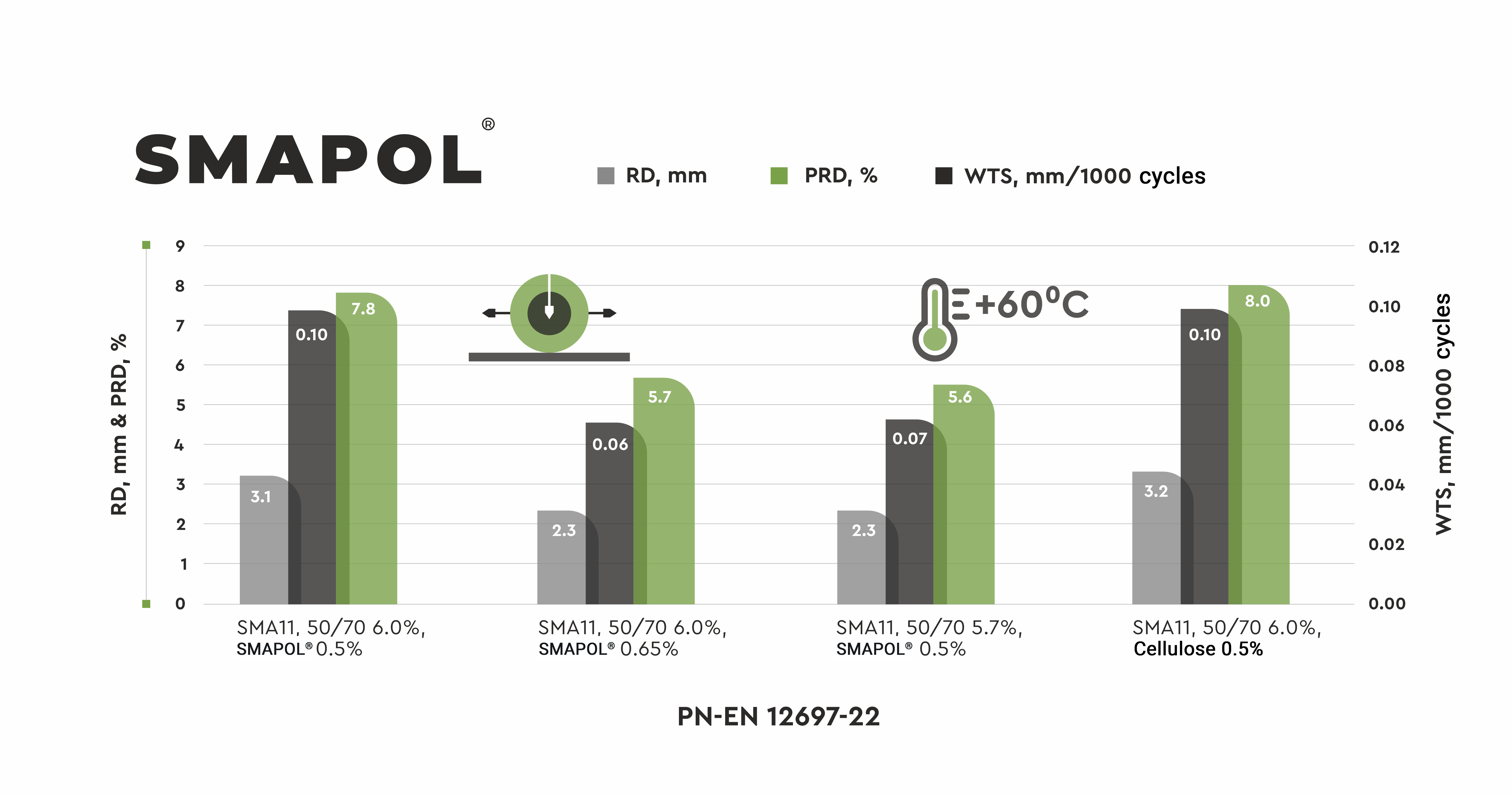

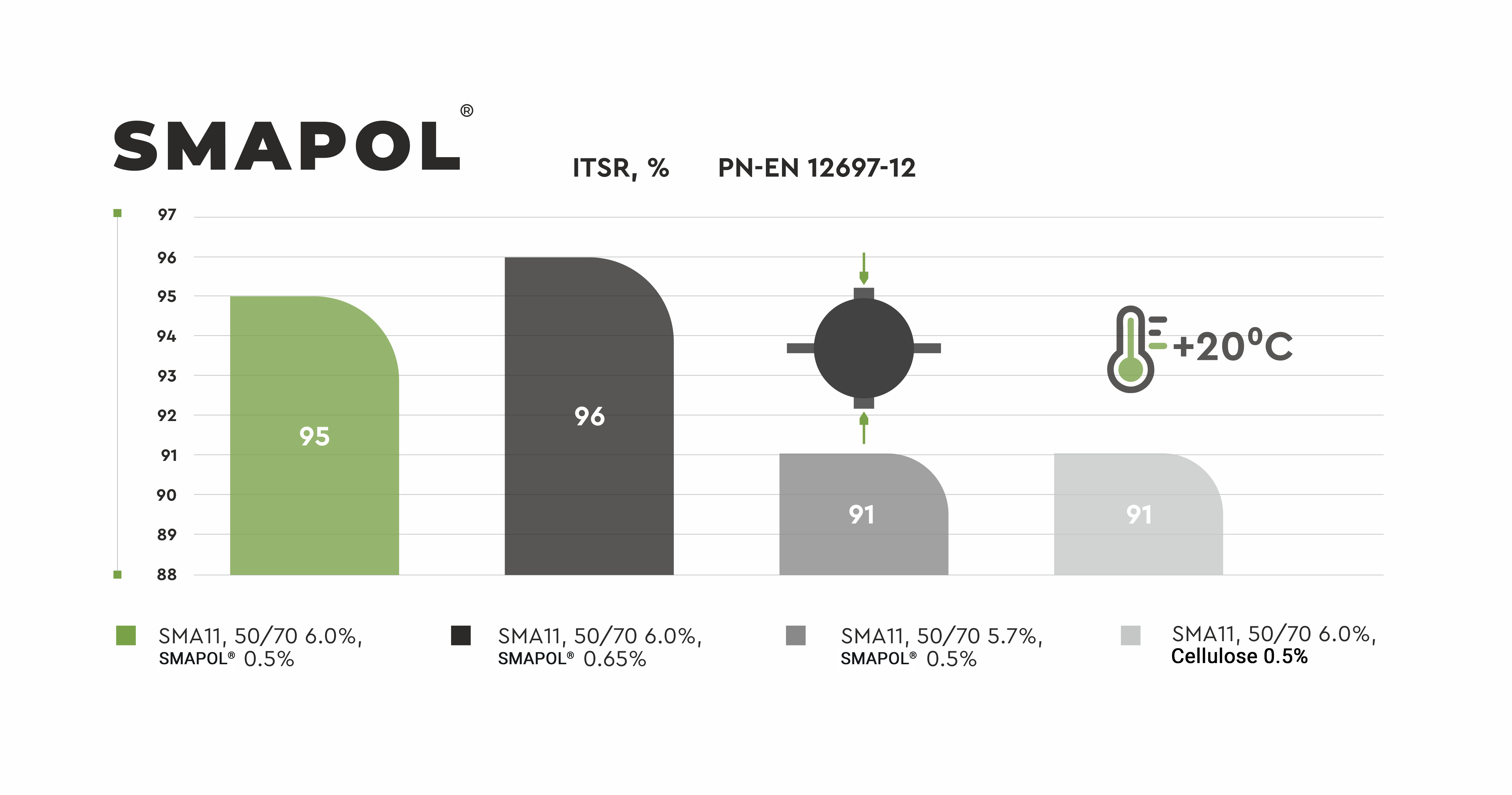

Compared to cellulose fibre-based stabilising additives, the SMAPOL® additive provides a more optimal degree of bitumen binder adsorption, allowing it to be used as a reinforcing ingredient in mineral-asphalt mixtures of all types.

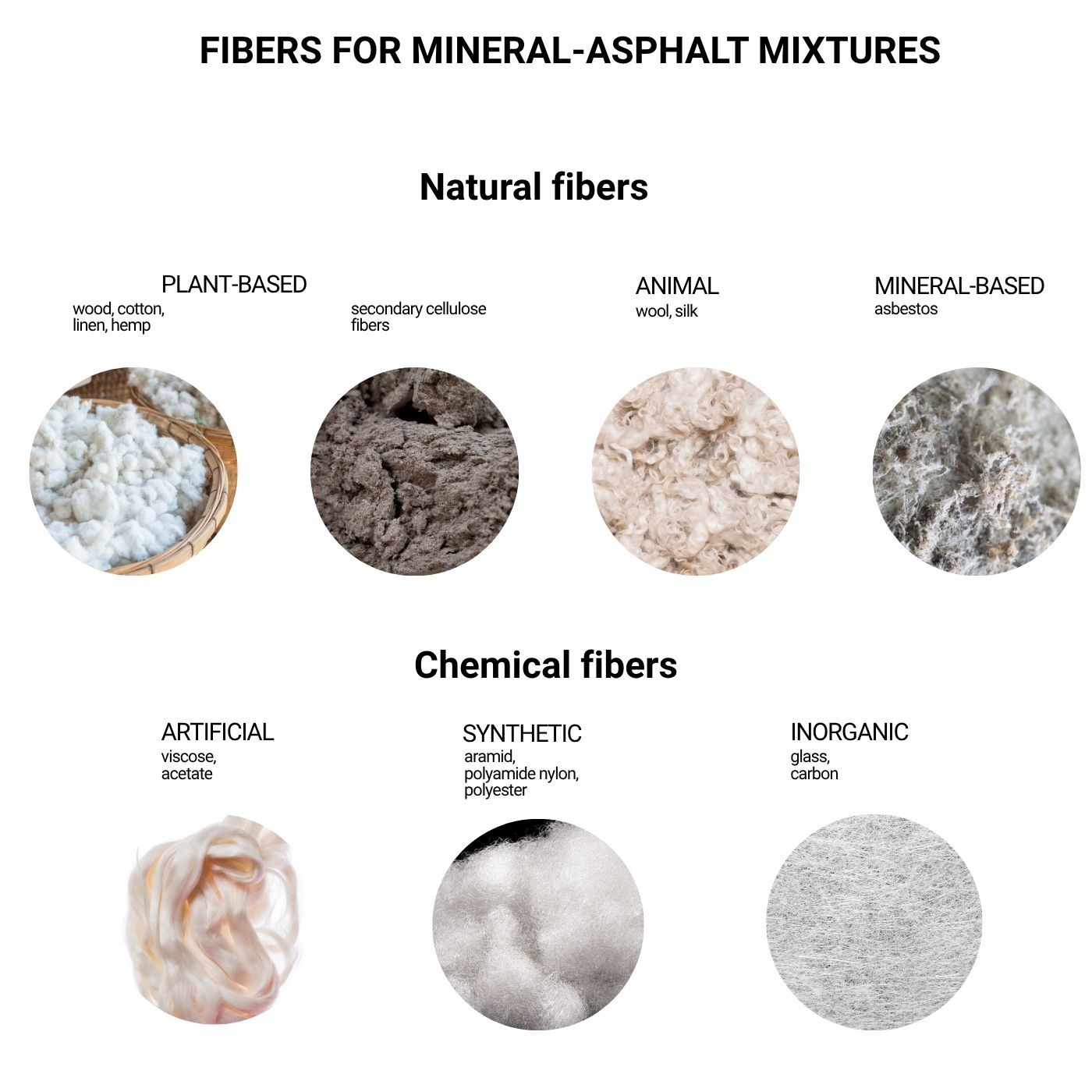

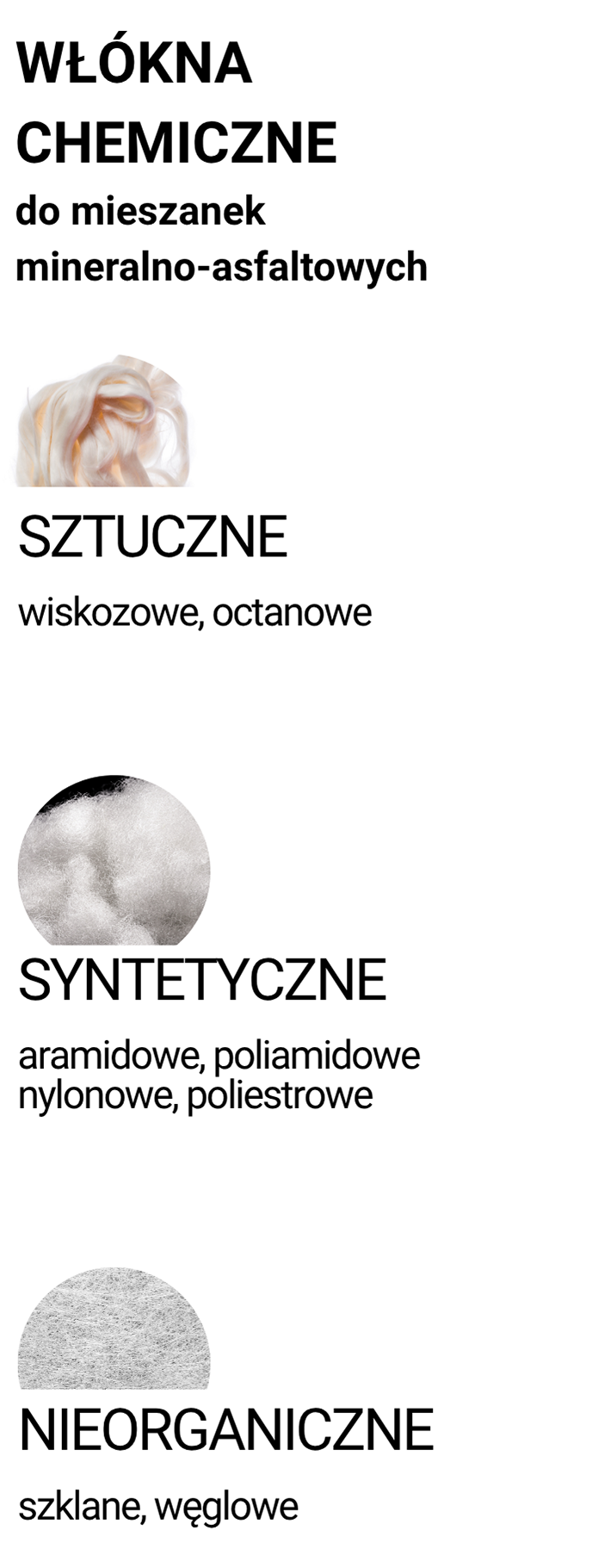

In worldwide asphalt pavement construction practice, various natural and chemical fibres are used as additives to asphalt mixtures to improve their strength, deformability and technological properties.

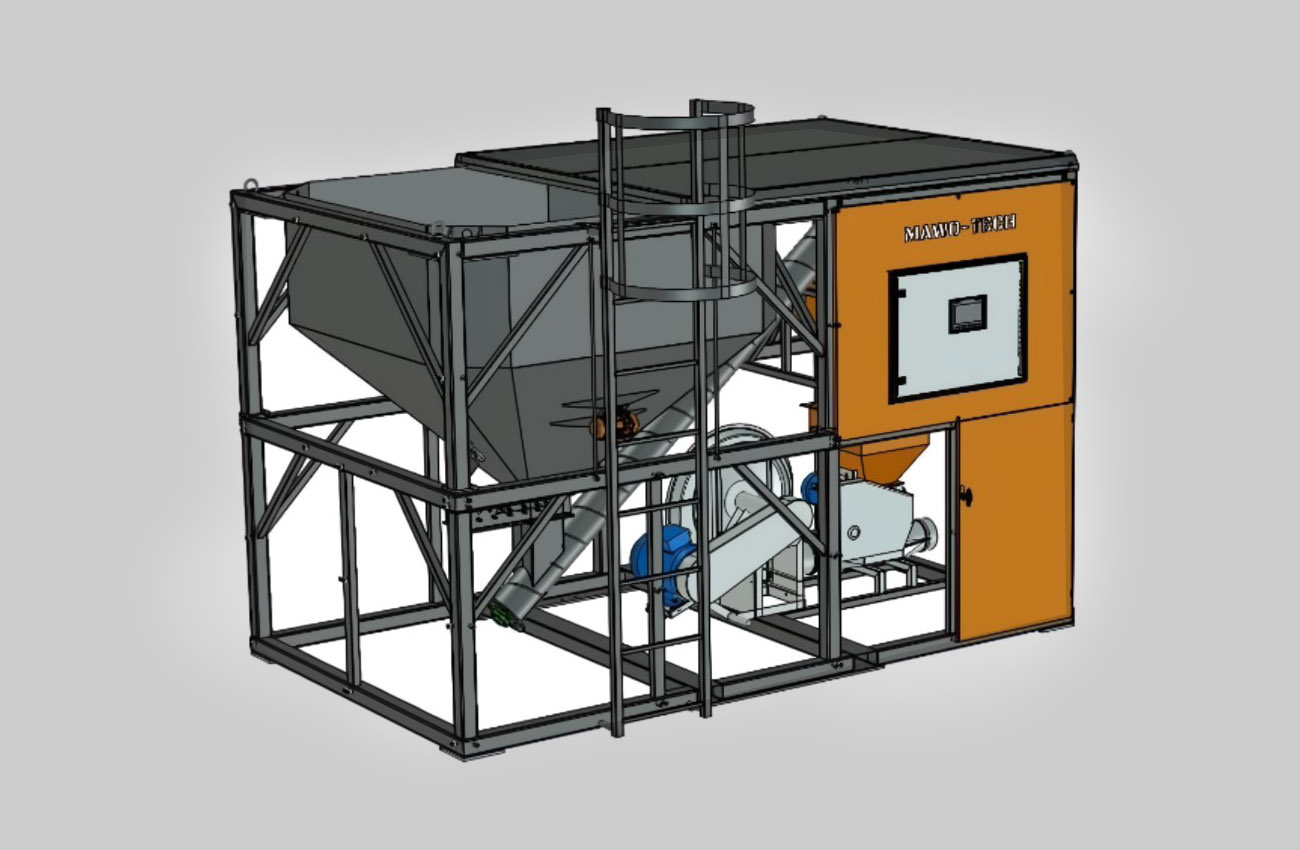

In the SMAPOL® production process, the multifibre blend, consisting of synthetic fibres, is optimised for the content of each fibre type, activated and modified. This results in a product with exceptional functionality and efficiency, including cost-effectiveness based on the level of cost of the way in which the properties of mineral-asphalt mixtures are improved.

SMAPOL® has the lowest carbon footprint among known stabilising additives and reinforcing fibres for mineral-asphalt mixtures and, at the same time, contributes to extending the durability of asphalt pavements. This has the effect of lowering the carbon footprint of road pavements over their lifetime.

Durability and cost-effectiveness of road pavements

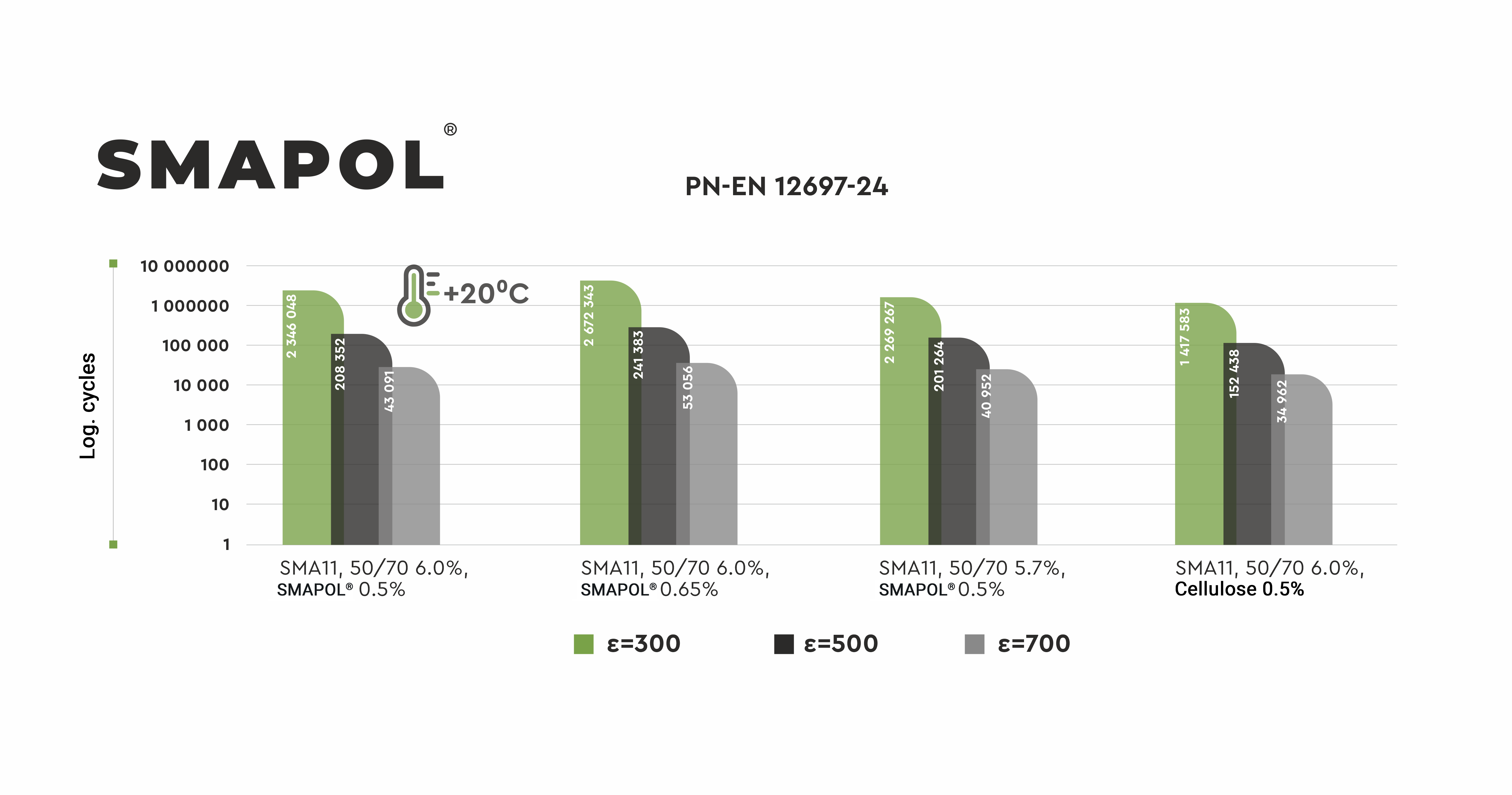

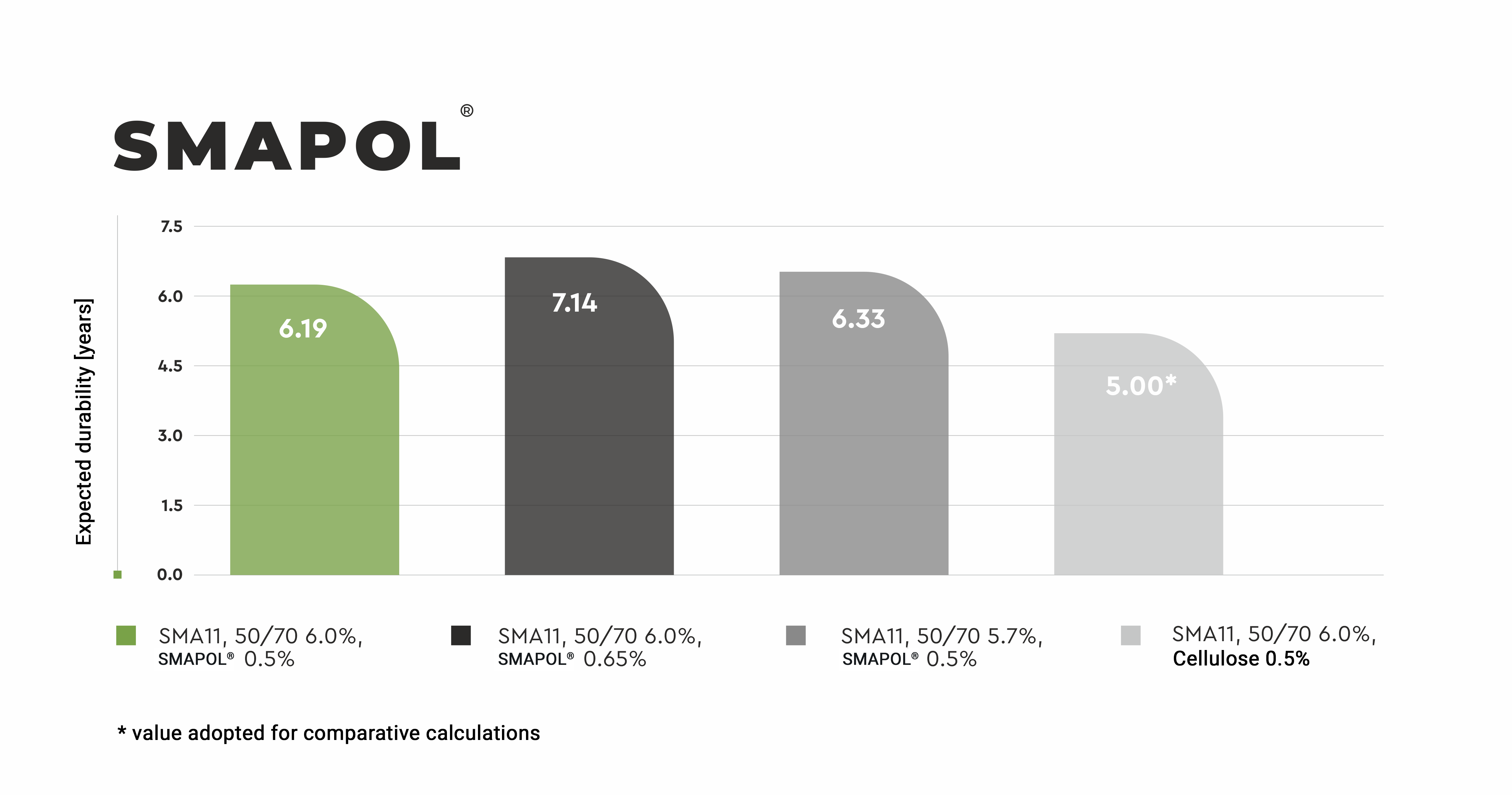

By using SMAPOL® instead of cellulose additives, you can expect not only a reduction in direct costs (the cost ofSMAPOL® on the Polish market is 1.6-1.75 times lower than that of cellulose additives), but also a measurable annual economic effect by extending the service life of road pavements by approximately 25-40%.

Reduced carbon footprint of road pavements

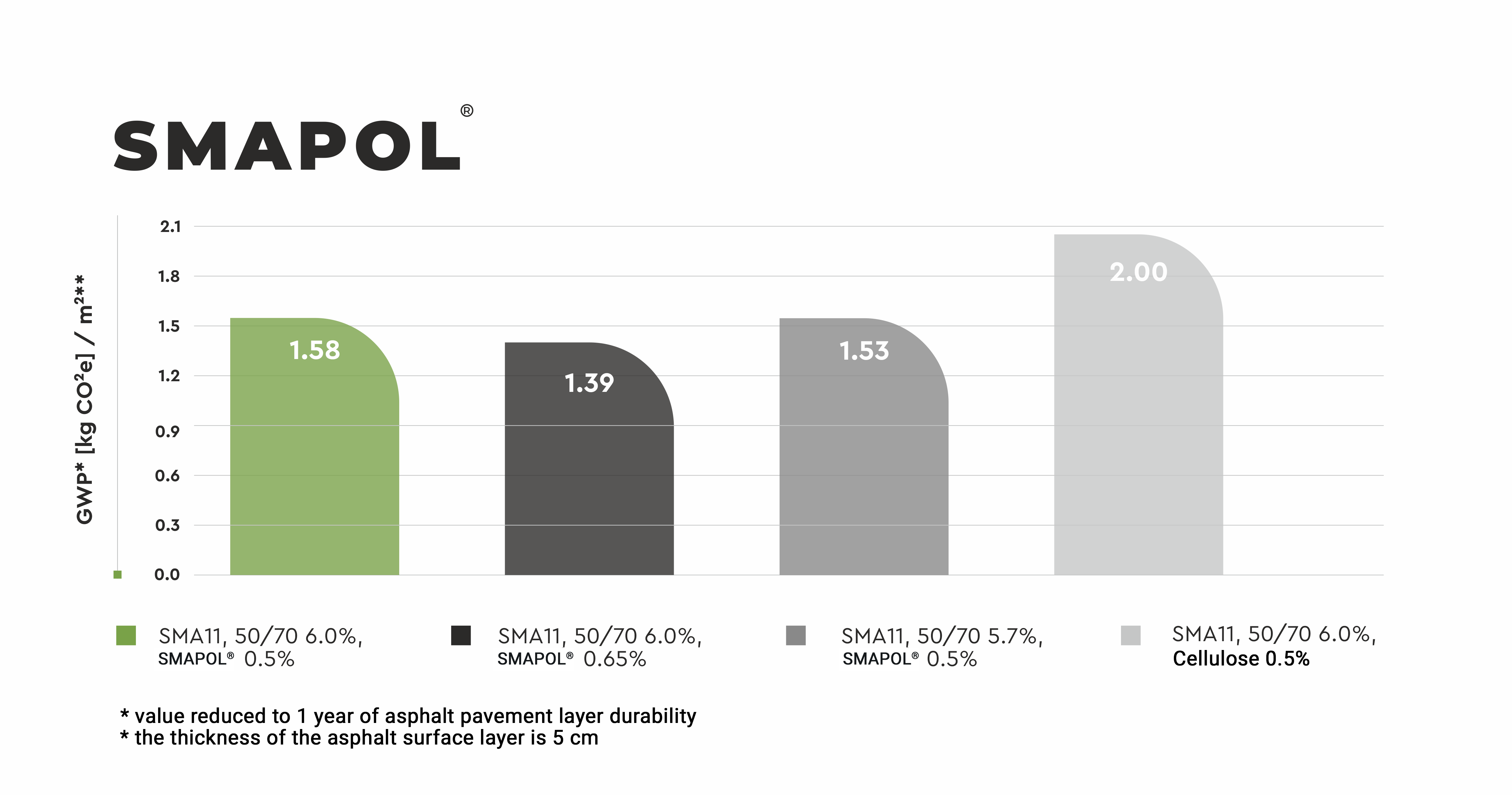

The level of environmental impact calculated by the Global Warming Potential (GWP, CO2e), reduced to the estimated durability of a pavement laid with SMA asphalt mixture with SMAPOL® additives, is 20-30% lower than for a pavement laid with SMA asphalt mix with cellulose additives.

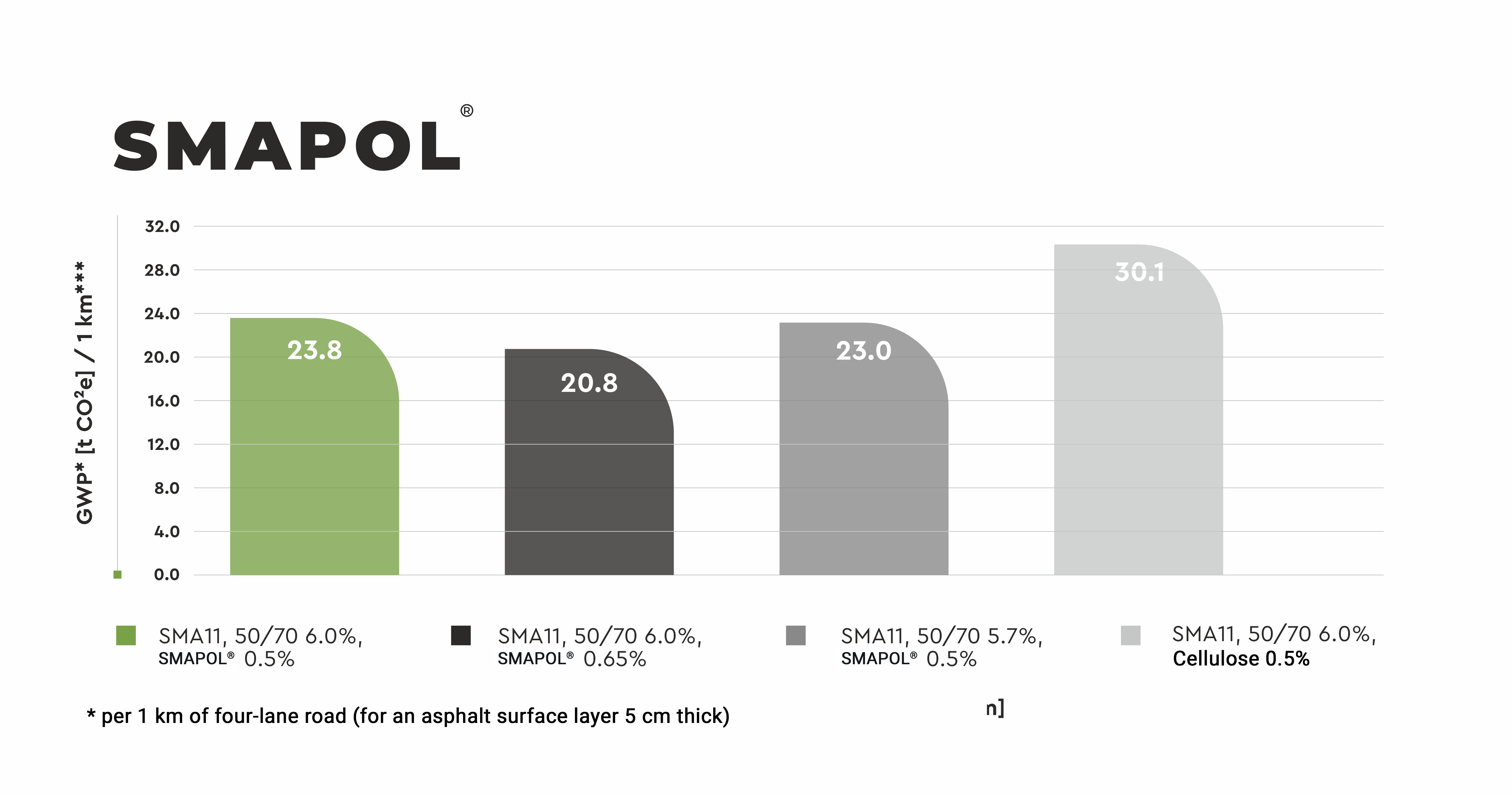

For 1 km of carriageway with two lanes, the use ofSMAPOL® instead of the cellulose additive will reduce the GWP (CO2e), reduced to 1 year of the estimated service life of the asphalt pavement, by 3-5 tonnes.

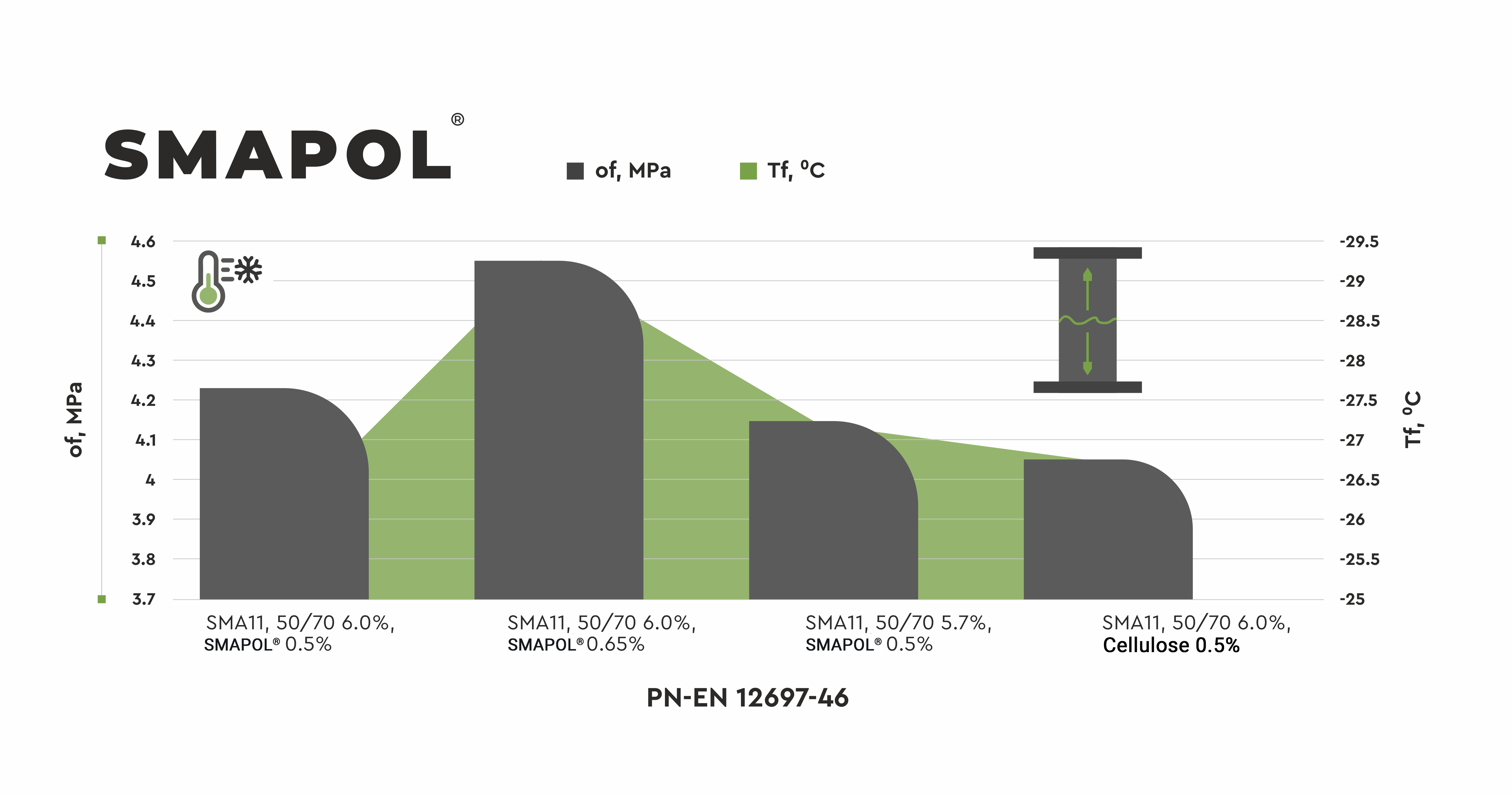

SMAPOL® performance

Professional support at every stage of SMAPOL® application

SMAPOL® – Polish construction product

National Technical Assessment

National Technical Assessment No. IBDiM-KOT-2023/0913

National Certificate of Conformity

National Certificate of Conformity for Factory Production Control AC152-UWB-PL23/1678