Stabilisation of the asphalt binder in SMA mastic and other discontinuous-grained mixes is necessary due to its increased thickness on the aggregates and should be ensured during transport of the mix to the construction site, its spreading and compaction into the road surface at high temperatures of approximately 150-180 °C. If the asphalt binder is not stabilised, it will run off, causing segregation and delamination of the asphalt mix, which will lead to damage to both the internal structure of the layer and its texture; for example, both ‘asphalt patches’ and areas of increased porosity may appear. This can lead not only to a reduction in pavement durability, but also to a reduction in traffic safety.

Today, cellulose fibre-based additives are almost universally used as binder stabilisers in SMA asphalt mixes. But should only cellulose fibres be used to eliminate asphalt binder run-off?

Let’s get to know the physical causes of binder run-off in SMA asphalt mixes.

Asphalt binder flowing off mineral particles at high temperatures is similar, for example, to paint flowing off a wall. But why the run off?

Let’s turn to rheology, a branch of science that studies the behaviour of liquid and plastic materials under mechanical stress. Eugene Bingham introduced the term rheology. He and Fedor Shvedov developed models to describe the rheological behaviour of distributed systems.

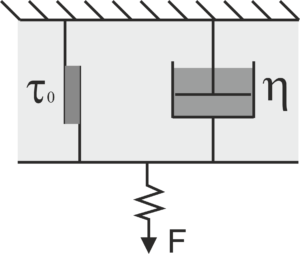

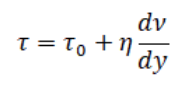

Dispersed systems include, for example, ordinary oil-based paints and asphalt binders (asphalt + mineral filler) at high temperatures. The Shvedov-Bingham equation describing the flow of a viscoplastic fluid generally looks as follows:

In a viscoplastic fluid, under a stress exceeding the yield strength τ0, the structure of the fluid layer collapses and the fluid flows to some extent similar to a Newtonian fluid with viscosity η.

For example, if an oil-based paint has an insufficient yield strength τ0 to hold onto a wall under gravity, it will start to flow and its viscosity η will determine the flow rate down the wall.

The same happens in thick layers of asphalt binder on aggregates in the SMA asphalt mix. When the operating temperature increases to 150-180 °C, the yield strength of the asphalt binder τ0 decreases and reaches the limit when the binder stops retaining on the mineral particles because of the stress due to gravity. The asphalt binder starts to flow and the rate (time) of its complete flow off the mineral particle depends on its viscosity η.

It is therefore necessary to ensure minimum rheological properties of the asphalt binder at high operating temperatures to prevent run-off in SMA asphalt mixes. This means that in order to prevent its unacceptable run-off: the yield strength τ0 must be higher than the effective shear stress due to the self-weight of the asphalt film; or, in order to provide sufficient run-off time to transport the asphalt mix and to spread and compact it into the pavement: the plastic viscosity η of the asphalt binder must have an adequate value.

It is therefore necessary to ensure minimum rheological properties of the asphalt binder at high operating temperatures to prevent run-off in SMA asphalt mixes. This means that in order to prevent its unacceptable run-off: the yield strength τ0 must be higher than the effective shear stress due to the self-weight of the asphalt film; or, in order to provide sufficient run-off time to transport the asphalt mix and to spread and compact it into the pavement: the plastic viscosity η of the asphalt binder must have an adequate value.

It then becomes apparent that no matter what ingredients are added to the asphalt binder, whether cellulose fibres or any other fibres, filler or polymer, all of these additives will alter its rheological properties, and their correct evaluation is the key to success in selecting a suitable and effective stabiliser. Very simple.

It is not without reason that one of the first patents for SMA asphalt mixes (US Patent No. 3797951, 1970) by G. Zichner, in order to ensure the technological stability of the binder, proposes the addition of polymers, fibres, fillers, etc., as stabilisers, i.e. any ingredients that can optimise the rheological properties of the binder at high operating temperatures.

And cellulose fibres are not unique in this matter, as they fail to improve the properties of SMA asphalt mixes. The SMA is good in itself because of its structural features. Cellulose fibre may be less necessary than any other stabilising ingredient, but no more than that. However, due to the high absorption capacity of cellulose fibres, for example, they cannot be added in great amount; the properties of the asphalt mix deteriorate, it dries out and its indices characterising long-term strength, water resistance and frost resistance decrease. Thus, the use of cellulose fibres is limited. And synthetic fibres or polymers, for example, can be added in much greater quantities, improving not only the technological properties of asphalt mixes (by reducing the flow rate of the asphalt binder), but also their strength and deformation properties.

So, does it make sense to continue using cellulose-based technologies for stabilising asphalt binders in SMA, which are old and static and require the constant use of far more expensive modified asphalts, because the cellulose fibres themselves do not significantly alter the properties of the asphalt binder or the micro- and macrostructure of asphalt mixes? The answer is obvious.

Benefit from modern, innovative, environmentally friendly and cost-effective solutions for stabilising and reinforcing asphalt mixes with synthetic fibres from recycled heavy-duty textile cords of end-of-life tyres.

The level of environmental impact calculated on the basis of the greenhouse effect potential (GWP, CO2e), reduced to the estimated durability of SMA asphalt pavement with synthetic fibre derived from end-of-life tyres, is at least 20-30% lower than that of SMA asphalt pavement with cellulose additives [1, 2]. Therefore, for a one-way road of 1 km with two lanes, the use of this fibre instead of cellulose additive can reduce the GWP (CO2e), reduced to 1 year of the estimated life of the asphalt pavement, by 3-5 tonnes.

Synthetic fibre asphalt pavements made from end-of-life tyres are more reliable and long-lasting, providing high technical and economic performance. Compared to cellulose fibre-based asphalt mixes, the increase in durability of asphalt mixes with a similar synthetic fibre can reach, according to our research [3], up to 20-40%, and according to research by other research teams [4], up to 100%.

Currently, the Polish company Recykl O.O. S.A. mass-produces the fibrous granular additive SMAPOL® for synthetic fibre asphalt mixes from end-of-life textile tyre cords.

SMAPOL® is a granular additive with a stabilising reinforcing effect, as its main ingredient is high-strength synthetic fibres (polyester, polyamide, viscose, aramid). SMAPOL® is dosed into the mixer at the mixing stage of the hot mineral materials, which does not affect the mixing time in any way, since during dry mixing the granules of the additive are only heated and the final homogenisation takes place at the wet mixing stage. SMAPOL® is not a mix of hard polymer granules, but consists of fibres, so it does not require additional mixing time compared to cellulose fibres.

SMAPOL® is a granular additive with a stabilising reinforcing effect, as its main ingredient is high-strength synthetic fibres (polyester, polyamide, viscose, aramid). SMAPOL® is dosed into the mixer at the mixing stage of the hot mineral materials, which does not affect the mixing time in any way, since during dry mixing the granules of the additive are only heated and the final homogenisation takes place at the wet mixing stage. SMAPOL® is not a mix of hard polymer granules, but consists of fibres, so it does not require additional mixing time compared to cellulose fibres.

As a stabilising additive, SMAPOL® is essentially similar to cellulose additives, i.e. As a stabilising additive, SMAPOL® is basically similar to cellulose additives, i.e. it prevents the asphalt binder in SMA asphalt mixes from running off during transport, spreading and compaction, but in addition, as it consists of high-strength synthetic fibres with an average length of approximately 2-5 mm, SMAPOL® provides microstructural reinforcement of asphalt mixes (not only SMA mixes, but also asphalt mixes of other types), ensuring, in contrast to cellulose additives, an increase in strength and deformation properties.

The SMAPOL® additive has passed the state evaluation procedure at the Research Institute for Roads and Bridges in Warsaw regarding its applicability in SMA asphalt mixes as an asphalt binder stabiliser. The production process is monitored annually by SGS for quality assurance.

Benefits of purchasing SMAPOL® – the use of a multifunctional additive for asphalt mixes, even at a lower price than cellulose stabilising additives.

SMAPOL®: it’s not just a replacement for cellulose additives in SMA asphalt mixes – it’s an improvement

Bibliography

An environmental evaluation. Procedia Manufacturing, 21, 329-336. https://doi.org/10.1016/j.promfg.2018.02.128

Martinez-Soto, A., Valdes-Vidal, G., Calabi-Floody, A., Avendaño-Vera, C., & Martínez-Toledo, C. (2022). Comparison of Environmental Loads of Fibers Used in the Manufacture of Hot Mix Asphalt (HMA) and Stone Mastic Asphalt (SMA) Mixes Using a Life Cycle Assessment (LCA). Sustainability, 14(21), 14246. https://doi.org/10.3390/su142114246

Zaprzalski, P., Zankowicz, W. (2023). Ekologiczny sposób recyklingu tekstyliów pochodzących z opon wycofanych z eksploatacji. Nowoczesne nawierzchnie drogowe. Recykling w konstrukcjach nawierzchni drogowych. MRP’23, 18.10.2023, Warszawa. Abstracts of papers. Road and Bridge Research Institute, 63-64. https://mrp23.ibdim.edu.pl/images/dokumenty/2023/10/streszcenia_calo_m.pdf

Vidal, G., Calabi, A., Mignolet-Garrido, C., Bravo-Espinoza, C. (2024). Enhancing Fatigue Resistance in Asphalt Mixtures with a Novel Additive Derived from Recycled Polymeric Fibers from End-of-Life Tyres (ELTs). Polymers. 16, 385. https://doi.org/10.3390/polym16030385

Dr inż. Witalij Zankowicz

R&D Manager for Road Technologies

RECYKL O.O. S.A. laboratory.